For more than 100 years, the Engler-Bunte-Institut has been dealing with the tension between scientific research and technical application with sustainable energy and water use in the sense of a safe and careful use of resources.

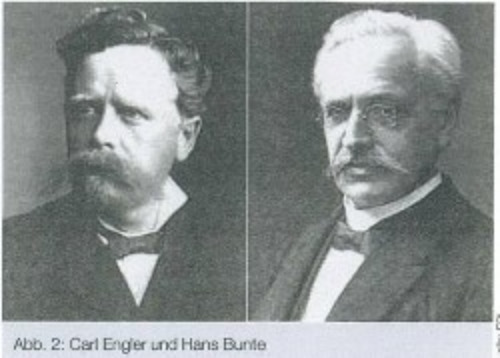

The Engler-Bunte-Institut focuses on the education and training of students and specialists as well as on the research and development of effective processes, analysis and measurement methods and their engineering principles. In 2007 the Engler-Bunte-Institut celebrated its 100th anniversary. The history of the institution testifies to the rapid technical development on which our modern civilization is based and reflects the far-reaching importance of energy and water research. The Engler-Bunte-Institut owes its success story to the cooperation of the state of Baden-Württemberg, represented by its University of Karlsruhe (TH), the city of Karlsruhe and the Karlsruhe municipal utilities as well as the DVGW German Association for Gas and Water - Technical Scientific Association e. V. and the gas industry. In 1903 the board of the DVGW decided to found a test gas station. In 1907 the DVGW's "teaching and testing gas institute" was officially opened and affiliated to the University of Karlsruhe (TH). Since 1971 the institute has borne the names of two outstanding scientists who significantly advanced chemical engineering and, in particular, chemical process engineering of fuels in their time: Professor Carl Engler, appointed to Karlsruhe in 1876, and Professor Hans Bunte, active in Karlsruhe from 1887 (see Illustration).

They worked as pioneers in the field of petroleum characterization and processing and coal-based public gas supply. Today the Engler-Bunte Institut is part of the Faculty of Chemical and Process Engineering of the Karlsruhe Institute of Technology (KIT) and comprises the areas of chemical energy carrier fuel technology (head of the institute: Prof. Dr.-Ing.Thomas Kolb), combustion technology (head of the institute: Prof. Dr.-Ing.Dimosthenis Trimis) and water chemistry (institute director: Prof. Dr. rer. Nat. Harald Horn) as well as the DVGW research center.

Chemical energy fuel technology division

The area of chemical energy carrier fuel technology, formerly the chemistry and technology of gas, petroleum and coal, deals in research and teaching primarily with the process engineering of the conversion and refinement of fuels before their use. Research and development focus on the fossil fuels gas, petroleum and coal, but also on renewable fuels such as B. biomass and waste, synthetic fuels such as hydrogen and Fischer-Tropsch products as well as environmental technology for fuel use in industry and households. The focus is primarily on the rational use of chemical fuels and the further or new development of the refining process, taking into account the latest scientific findings. Current research focuses on the production of synthetic fuels from biomass. Several publicly funded research projects are dedicated to fundamental investigations into the thermal gasification of biomass. A focus here is on experimental investigations into the formation of soot and tar during entrained flow gasification of biomass pyrolysis oils. The aim is to determine the optimal operating parameter window for the subsequent syntheses. Another topic is investigations into the "chemical quenching" of raw synthesis gases, whereby the thermal energy of the raw gas is used to improve the overall efficiency of the gasification. The project is carried out in close cooperation with the Karlsruhe Research Center. The work on the production of tar- and soot-free synthesis gases is supplemented by scientific work on the downstream syntheses (SNG and Fischer-Tropsch synthesis). The decentralized hydrogen production and purification, especially with regard to the application in PEM fuel cells, has been a research area at the chair for a long time. Through the work on sulfur-tolerant reforming, desulphurization, water-gas shift reaction and residual CO removal, all relevant procedural process stages of this application are covered. Fuel-related aspects of SOFC fuel cells for stationary (FC heating) and mobile (APU systems) applications are also dealt with in the research work of the chair. These include reforming and desulfurization studies.

Combustion technology division

The subject of research activities in the area of combustion technology are the processes taking place in flames, which are characterized by a complex interplay of chemical reactions and transport processes. To this end, scientists examine the flames experimentally using complex measuring techniques. On the other hand, they calculate the physical and chemical processes using mathematical models. With the knowledge gained from the research work, existing combustion processes can be optimized and new, future-oriented concepts such as B. the flameless oxidation in gas turbines, the lean burn in the aircraft engine or the homogeneous self-igniting internal combustion engine develop. The main aim is to increase efficiency and minimize emissions of carbon dioxide and pollutants. The researcher’s area of responsibility also includes developing problem-solving solutions that are flawless in terms of safety, in order to avoid damage from explosions or fires.

Water chemistry devision

The main areas of activity in the area of water chemistry are water treatment, drinking water supply, swimming pool water treatment, wastewater disposal and water protection. Research and development are based on the current molecular problems of water management: analysis of anthropogenic and biogenic substances in water, oxidation and disinfection processes including the resulting by-products, separation processes with membranes and their combination with classic processing processes (hybrid systems), biochemical conversions and elucidation of the degradation pathways of Substances that are considered to be toxic intermediates. The focus is on knowledge of the molecular dimension of the substances contained in water, their occurrence, their behavior and their reactions. The investigations include determination methods and reactions of substances contained in water in bodies of water and in technical water treatment. Specially developed and powerful analysis methods enable the identification of pesticides, pharmaceutical products and other organic synthesis products as well as industrial chemicals down to the concentration range of nanograms per liter.

DVGW research center

The DVGW research center at the Engler-Bunte-Institut is a non-profit organization of the DVGW at the Karlsruhe Institute of Technology (KIT). It is checked, monitored and certified in conjunction with the DVGW. The DVGW research center conducts practical research in close cooperation with the sub-institutes of the Engler-Bunte-Institute. The employees advise companies in the gas and water sector, develop the fundamentals of practical procedures and are involved in many different national and international standardization work.

Gas testing laboratory

The gas testing laboratory is recognized throughout Europe and has the technical prerequisites and facilities for all tests required in the gas field, including additional tests for obtaining certain quality or environmental labels. On the one hand, material tests are carried out on sealing materials, membranes, lubricants, etc. On the other hand, in addition to safety tests on all fittings and devices for gas supply and use, tests of electrical safety and electromagnetic compatibility are also carried out.

Technology consulting gas

is a competent contact for industry and gas supply companies in matters of safe and environmentally conscious processing, distribution and use of gaseous fuels. Current research projects deal, among other things, with the generation and processing of methane from biomass. As part of the DVGW research project G1 / 04/07 "Process-related consideration of the purification of biogas", technical, economic, ecological and legal aspects of biogas upgrading are examined. In addition, the production of methane from wood through gasification and subsequent methanization of the synthesis gas was taken up.

Department of Water Technology

The water technology department promotes the supply technology-oriented development of analytical methods. The trend-setting methods for eliminating unpleasant water pollution are also of particular importance. For example, microparticles and macromolecules are successfully separated from the water using innovative membrane modules. Materials that are otherwise difficult to separate are eliminated using fast and energy-efficient oxidation processes. Finally, innovative processes are tested together with water supply companies and swimming pool operators and made ready for use.

Authors:

Frank Graf

Rainer Reimert

DVGW-Forschungsstelle am Karlsruher Institut für Technologie (KIT)